ITER Organization Prepares for Retreat From Beryllium Design Objective

By Steven B. Krivit

July 26, 2023

The ITER Council is considering changing the plasma-facing first-wall material from beryllium to tungsten, the ITER organization announced on June 22, 2023.

Beryllium has always been part of the design for the International Thermonuclear Experimental Reactor. Yet, for a promised energy technology that is claimed to be environmentally benign, the use of beryllium is anything but.

Beryllium is a key material needed for fusion reactors to produce their own fuel. While not essential for ITER, it is essential for any reactor that would follow ITER. It’s so important that, several years ago, scientists re-lined the interior of the Joint European Torus reactor with beryllium specifically to test its performance, in anticipation of the use of beryllium in ITER.

Any reactor that follows the ITER design must be able to produce its own fuel. New Energy Times has reported on many fusion fuel issues. Beryllium is an essential component in the fusion fuel cycle.

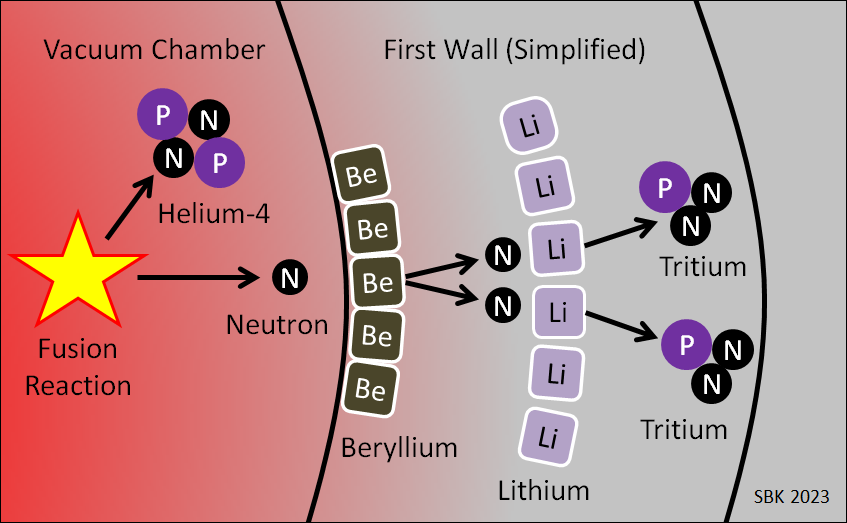

Beryllium has the unusual property of spitting out two neutrons when it is impacted by one neutron. In a working fusion reactor, this neutron multiplication process would need to take place inside the first wall of the reactor. When those neutrons produced by the beryllium reaction subsequently react with lithium-6, tritium is produced.

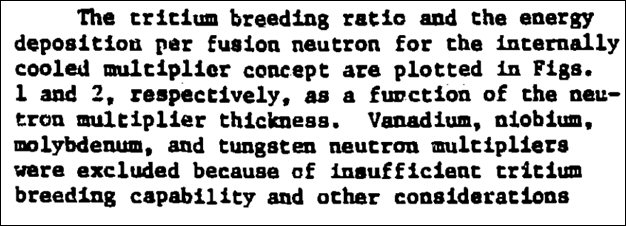

Without a neutron multiplier like beryllium or lead, a fusion reactor would not be able to produce enough tritium and would soon run out of the fuel that it is supposed to produce and consume. Fusion experts have known this for at least 43 years:

Paragraph from Y. Gohar and M.A. Abdou, “Neutronic Optimization of Solid Breeder Blankets for STARFIRE Design,” Oct. 1980

Whistleblower

Here’s how and why the ITER organization began its retreat from beryllium. On Feb. 8, 2022, Catherine Creek contacted me. As a whistleblower, she wanted my help to inform workers at the ITER site about the biological hazards of using beryllium in the construction of the reactor.

Beryllium is one of the most toxic materials on Earth. It is more dangerous than asbestos. It is more dangerous than the hexavalent chromium, made famous by the investigative work by Erin Brockovich. Creek explained more about the beryllium risks to New Energy Times:

Exposure to beryllium can result in a debilitating lung disease called Chronic Beryllium Disease. Beryllium metal is highly toxic to humans having the lowest occupational exposure limit of any metal outside radioactive metals. Effective control of beryllium takes enormous amounts of resources, money, and time similar to managing radioactive dust.

At the time, Creek was a beryllium occupational hygienist at the ITER Organization. Creek is a certified industrial hygienist who has more than 30 years of experience in occupational health and safety management, specializing in the evaluation and control of beryllium exposure hazards and beryllium facility design. Before coming to ITER, she worked for 25 years at the Los Alamos National Laboratory.

Her husband, Robert Winkel, was the beryllium coordinator at the ITER Organization. He is a certified industrial hygienist with 30 years of experience in occupational health and safety management, with a specialty in the evaluation and control of beryllium exposure hazards and beryllium facility design.

Creek told me that she and Winkel had informed Bernard Bigot, the former director-general of the ITER organization, of the beryllium risks but that he showed no interest in implementing sufficient safety procedures.

“The ITER organization had thought very little about a beryllium program manager before I came,” Creek wrote. “The position was not in ITER’s organizational chart. I wrote their Beryllium Management and Control Program and the Beryllium Facility Design Guide.”

With 12 tons of beryllium needed to line the inside walls of the ITER reactor, it would be the largest single installation to use the material. It would need to be cut and machined to fit into 440 panels that that would compose the inner wall of the reactor.

After the reactor is in operation, Creek said, plasma neutron penetration from the fusion reactions will induce corrosion, which will lead to airborne contamination. With the myriad ports, pipes, and doors going in and out of the reactor chamber, the design has inherent flaws that will probably result in insufficient protection of workers if beryllium is used.

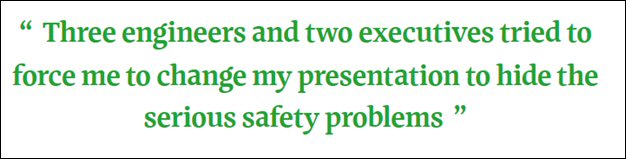

For Creek, the end of her internal attempts to protect workers came just before she was about to give a presentation for an internal nuclear safety review on the Hot Cell Complex Building. Her manager, Spencer Pitcher, wanted her to water down the risks she was planning to explain. Creek told him that she would do no such thing.

I was unable to report Creek’s story at the time so I referred her to environmental journalist Celia Izoard, who reported it in this article. Here’s a quote from that story:

After making their best effort under the previous ITER management to ensure worker safety, Creek and Winkel resigned. Creek told New Energy Times today that she is pleased to hear the news.

“Congratulations to the new management and leadership of ITER that is considering this very hard, yet wise decision that will prioritize worker’s health,” Creek said.