#91 ITER Fusion Reactor Fails Nuclear Regulatory Agency Inspection

Return to ITER Power Facts Main Page

By Steven B. Krivit

Nov. 10, 2021

Autorité de Sûreté Nucléaire ITER Inspection Report July 2, 2021

ITER, the International Thermonuclear Experimental Reactor under construction in France, has failed a periodic inspection by ASN (Autorité de Sûreté Nucléaire), the French nuclear regulator, New Energy Times has just learned. The ITER organization has not publicly disclosed the four-month-old report, which New Energy Times located on the ASN Web site last week.

The ASN Report

In the report, the most serious issue identified by the inspectors was that parts of two very large components, sectors of the vacuum vessel, fell during manufacturing and sustained damage. The ASN report does not provide details of the damage.

The report also states that inspectors discovered the forgery of certificates of welder qualifications, found gaps in welds, and detected leaks in cooling tower basins. Inspectors wrote that one of the areas at the reactor construction site was not accessible to them on the day of the inspection. Inspectors also noted unsatisfactory responses to their requests for documents from the ITER organization.

The inspection took place on July 2, 2021, and ASN sent the report on July 20, 2021, to Bernard Bigot, the director-general of the ITER organization. The failure of the organization to publicly disclose the report and publicly respond to the issues raised in the report is alarming.

ITER is a public science project funded by taxpayers representing half the world’s population. It is a nuclear experiment that is pushing the boundaries of fusion science. The public has a right to know of safety lapses uncovered in a regulatory inspection, as do the members of the staff working on the project.

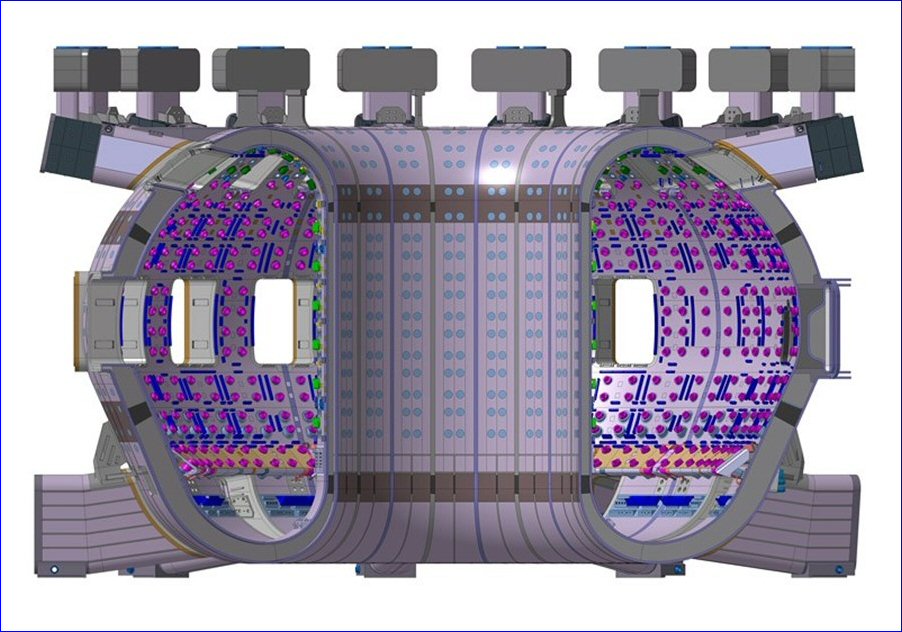

Vacuum Vessel

The central part of the reactor is called the vacuum vessel. It is composed of nine D-shaped sectors. When welded together, they will form the chamber in which the fusion reactions will take place. Each sector comprises 440 tons of steel.

Tiny Tolerances

According to the ITER organization’s Web site, “positional tolerances for the largest components, including the magnet coils and the vacuum vessel, are as low as two millimeters.” Here are the key comments from the ASN report on the two damaged vacuum vessel sectors:

French: Des éléments de secteurs de la chambre à vide ont chuté lors de manutention sur les sites de fabrication, en Corée du Sud en avril 2021 et en Italie en mai 2021. L’équipe d’inspection s’est intéressée à la gestion de ces écarts et à la préparation des réparations nécessaires. L’analyse des causes n’était pas encore aboutie pour les 2 écarts et certains documents concernant les réparations pour la chute sur le site italien n’étaient pas disponibles le jour de l’inspection.

English: Parts of the sectors of the vacuum chamber fell during handling at the manufacturing sites, in South Korea in April 2021 and in Italy in May 2021. The inspection team looked at the management of these deviations and the preparation of the necessary repairs. The root cause analysis was not yet completed for the 2 deviations, and some documents concerning the repairs for the fall at the Italian site were not available on the day of the inspection.

If the parts sustained dimensional distortion when they fell, it may not be possible to bend the components back to the correct dimensions. Some sort of repair, if possible and if approved by the regulator, will be necessary. If repairs satisfactory to the regulators cannot be made, the project will suffer yet another major delay while waiting for replacement parts to be manufactured in Korea and Italy and delivered to France.

In a report on the previous inspection, from March 30, 2021, inspectors wrote that “questions persist about the qualification of manufacturing materials and welds” about the vacuum vessel pressure suppression system. Inspectors were also concerned about protection of the system with regard to fire resistance.